Ma kekahi mau hana hana metala koʻikoʻi, e like me ka ʻoihana hana moku, nā mīkini mining, a me nā mīkini hana, ʻike pinepine ʻia ia mau pilikia: pehea e hoʻokō ai i ka hoʻopili paʻa ʻana o nā ʻāpana metala a me nā ʻāpana metala?ʻO ka maʻamau, e hōʻike ana nā ʻāpana metala i kahi ʻoki ʻoki ma hope o ke kaʻina ʻoki maʻamau.I mea e hoʻohui ʻia ai nā ʻāpana o nā ʻāpana i hoʻohui ʻia, pono e hana i nā bevels o nā ʻano geometric like ʻole ma nā ʻaoʻao o nā ʻāpana ʻelua, a laila e hana i ka hoʻopili ʻana i ka maka hope.I kēia mau lā, ua hoʻolaha ʻo Knoppo i ka KP Series (mana mai 30000W a 8000W) Pepamīkini ʻoki bevel fiber laser, ka mea e hoʻoponopono ai i nā pilikia welding, e hōʻemi i nā kaʻina hana paʻakikī, a mālama nui i ka manawa a me ke kumukūʻai.

Ma muaʻoki laser fiberʻenehana, ua hoʻohana ʻia ka ʻenehana ʻokiʻoki bevel i nā ʻano hana hana metala e like me ke ahi a me ka ʻoki plasma.Eia nō naʻe, ʻo ke ʻano o ka ʻoki ahi maʻamau e hana i nā ʻoki hohonu, a no nā trajectories paʻakikī, pono ka mākaukau a me ke kūlana hana o ka poʻe limahana e ʻoi aku ka ʻoihana, a ʻaʻole hiki ke hoʻokō maikaʻi ʻia ke kūlike o ka welding;ʻokiʻoki plasma ākea, e hopena i ka pololei haʻahaʻa haʻahaʻa, a e hana ʻia nā pōʻino e like me ka radiation arc, ka uahi a me ka walaʻau i ke kaʻina ʻoki.

ʻO nā ʻano hana ʻoki ʻelua ma luna aʻe e pili ana i ke ʻano hana hoʻokomo kumu wela nui.E hoʻoheheʻe ʻia ka pā ma lalo o ke ʻano hana wela, a pono e hana ʻia ke kaʻina deformation inverse ma hope o ka pau ʻana o ka hana.Ke hoʻohālikelike ʻia me ke ʻano beveling maʻamau, ʻo ka laser kahi ʻano hana hou me ka liʻiliʻi liʻiliʻi o ka thermal deformation, ʻoi aku ka maikaʻi o ka incision maikaʻi, ke kiʻekiʻe kiʻekiʻe a me ka paʻa maikaʻi loa i ka mākeke.

Knoppo KP moʻopepa fiber laser beveling mīkini ʻokihiki ke hoʻomaikaʻi maikaʻi i ka paʻa kuʻi, ka hui kuʻi ʻana a me ka mea hana aesthetics ma ka hoʻoponopono ʻana i ke awāwa o kekahi ʻano geometric i ka ʻāpana e hoʻopili ʻia o ka weldment.No ke kila kila, hiki i ke awāwa ke pāʻani i ka hoʻoponopono ʻana i ka ratio o ka metala kumu a me ka metala hoʻopiha.

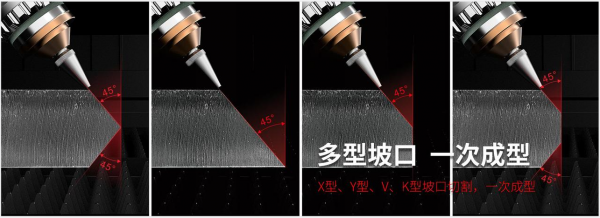

Wahi a ka mānoanoa like ʻole a me nā waiwai kino o nā papa like ʻole, ʻokoʻa hoʻi ke koho ʻana o nā ʻano beveling.ʻO nā ʻano beveling maʻamau ma ka mākeke, ʻo ia ka X-shaped groove, V-shaped groove, Y-shaped groove, K-shaped groove, etc. kaʻina hana hope-weld.Ke piʻi aʻe ka mānoanoa o ka weldment, hoʻohana mau ʻia ke ʻano K-like groove a i ʻole ka X-shaped groove.Ma ka mānoanoa like, hiki ke hoʻemi ʻia ka nui o ka weld metala ma kahi o 1/2, a he symmetrical ke kuʻi ʻana, a he liʻiliʻi ka deformation ma hope o ke kuʻi ʻana.

He aha ka knoppo fiber laser beveling mīkini ʻoki?

ʻO ka mea mua, hiki ke hana pololei ʻia ke ʻano o ke ʻano geometric ma ka ʻāpana e hoʻopili ʻia o ka weldment, i hiki ke loaʻa i ka welding seam me ke komo piha ʻana o ka mānoanoa welding i ke kaʻina hana hoʻoheheʻe hope, i mea e hōʻoia ai. ka ikaika welding o ka weldment a hōʻemi i nā kaʻina hana pono ʻole., e hoʻokō i ka hopena multiplier;

ʻO ka lua, ke hoʻohālikelike ʻia me ka hoʻoheheʻe ʻana o ka lapalapa a me ka plasma bevel, ʻoi aku ka maikaʻi o ka hana laser a mālama i nā mea.No ka laʻana, i ka ʻoihana hana moku, ʻo ka hoʻohana ʻana i ka ʻenehana ʻokiʻoki ʻana i ka laser bevel no ka hoʻoponopono ʻana i nā ʻāpana T-like o ke kila haʻahaʻa haʻahaʻa hiki ke hoʻopakele nui i nā mea hao hao ʻoiai e hōʻoiaʻiʻo ana i ka paʻa o ka moku;

ʻO ke kolu, ʻo ka hoʻoili ʻana i ka laser ka maikaʻi o ka deformation thermal liʻiliʻi, ka maikaʻi ʻoki paʻa a me ka pololei kiʻekiʻe.Maikaʻi ka splicing.

I kēia manawa, ua hoʻokō ka ʻenehana ʻokiʻoki ʻo Knoppo laser bevel i ka uhi piha i ka hoʻoili ʻana i ka metala a me ka hoʻoili ʻana i ka profile, a ʻo ka ʻenehana ka nui o nā noi, e uhi ana i ka hana moku, ka pahu hau ʻenehana, nā mīkini hana, nā mīkini mining, nā paipu aila, etc.

Ka manawa hoʻouna: Jul-08-2022